Photovoltaic Processing Solar Panel Manufacturing

And for lighting pumping and medical refrigeration for villages in developing countries.

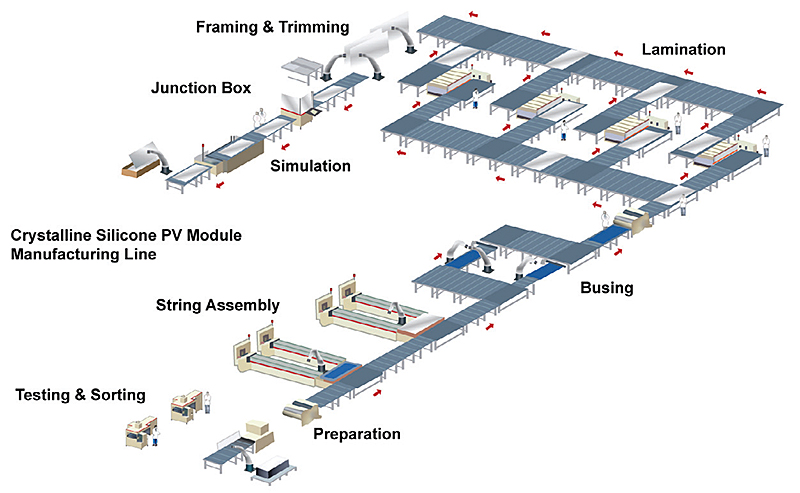

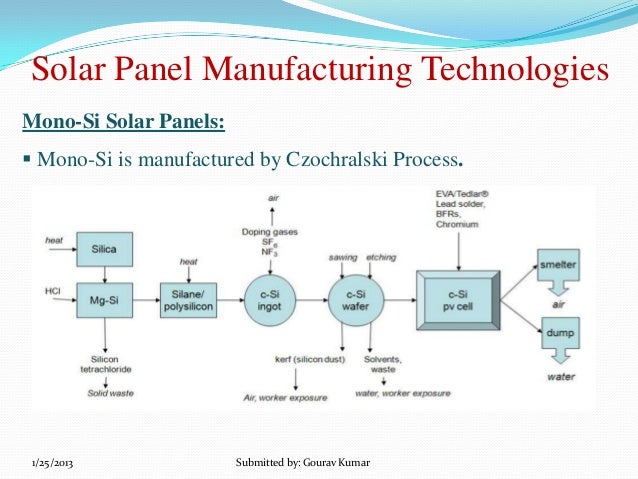

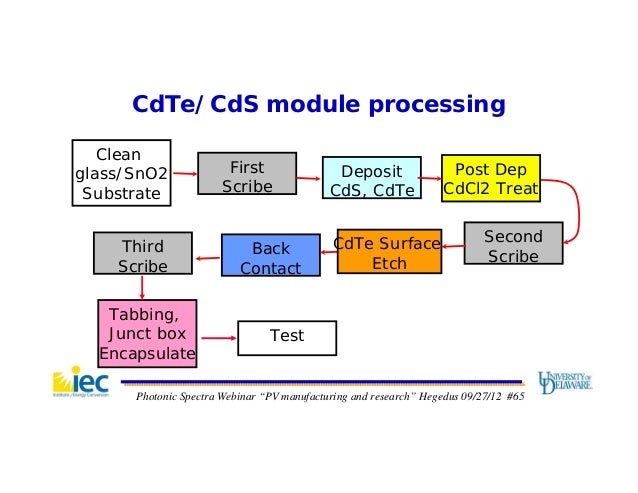

Photovoltaic processing solar panel manufacturing. The manufacturing process of crystalline silicon solar cells is as below diagram. The specific manufacturing process is as below. Most of rec s solar pv systems are typically priced between 2 44 and 3 06 per watt which makes them a strong value in the market for home solar panels. The production of crystalline solar modules.

Auxin solar is a solar manufacturing success story that charles bush hopes to repeat in richmond virginia. Are sunrun and tesla. The manufacturing technique for solar cells. Currently the top 3 solar manufacturers in the world are jinkosolar ja solar and trina solar respectively determined by market share among panel manufacturing companies.

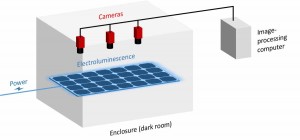

Learn more about the components and the process of manufacturing a solar panel. Calculators and other small devices. Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight as distinguished from a solar thermal module or solar hot water panel the electrical energy generated from solar modules colloquially referred to as solar power is an example of solar energy. The biggest solar installation companies in the u s.

The top 3 solar manufacturers. Bush bought a 16 000 sq ft former die plant in richmond and spent 1 2 million to set it up as a panel assembly facility and he s actively looking for manufacturers to partner with. Rooftop panels on individual houses. Photovoltaic cells make electricity from sunlight.

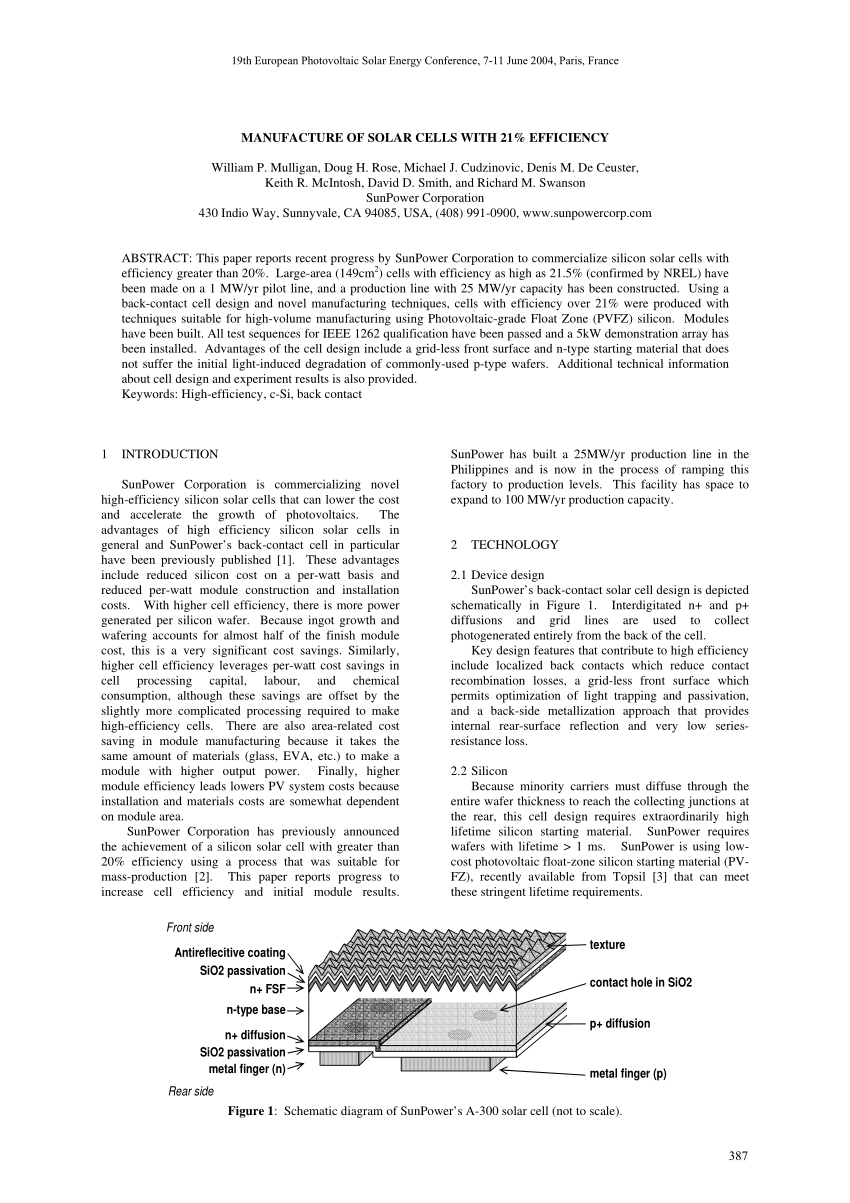

While most solar panel manufacturers offer a ten year materials warranty rec provides a maximum of 20 year warranty against any defects in their solar panels. We ll look at the manufacturing process for most common panels photovoltaic or pv. Finally the structure is then. It is the developing mainstream of solar cells technology to improve conversion rate of solar cells and decrease cost.

The company is equipped with industry leading equipment and has thousands of. The manufacturing process adopts world leading production technology high quality production process and the supply chain spreads all over the world. Photovoltaic solar cells are thin silicon disks that convert sunlight into electricity. Thin film solar panels.

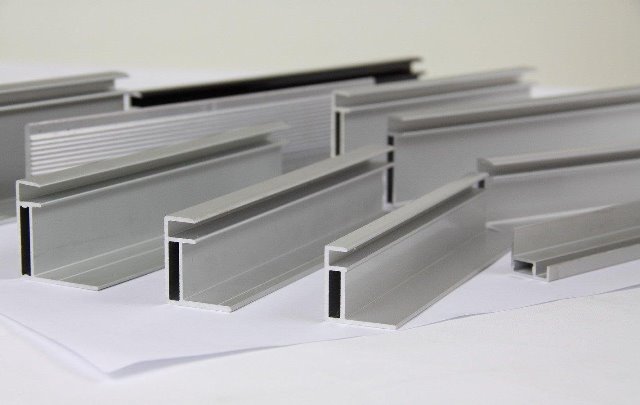

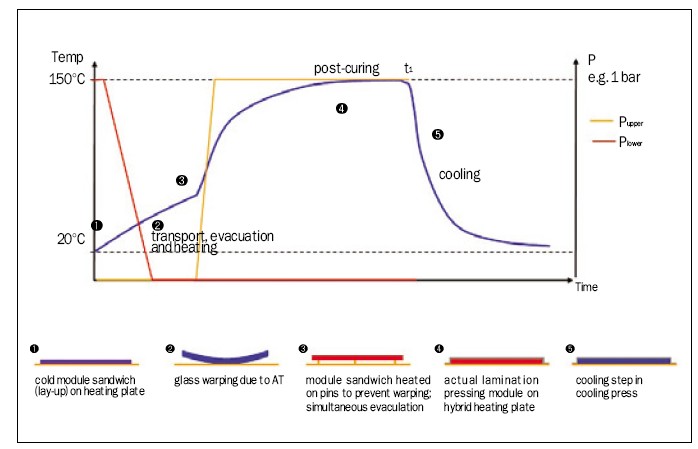

Basically they do this by enabling light particles from the sun to knock electrons from atoms in the pv cells. A solar pv module consists of solar cells glass eva backsheet and frame. This is the so called lamination process and is an important step in the solar panel manufacturing process. These disks act as energy sources for a wide variety of uses including.

There were some major changes over the past few years including some new leaders in solar manufacturing who were. Here s how a solar panel is put together to do just that on your rooftop day after day.

.jpg)

.jpg)

.jpg)