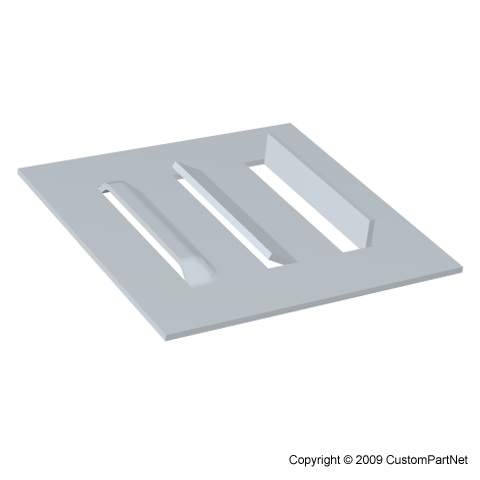

Partial Cut On Sheer Sheet Metal

Great ways to cut metal with eastwood tools.

Partial cut on sheer sheet metal. If you d like to learn more about ablative laser cutting check out this article on micron scale manufacturing. Double cut shears cut on both sides of the blade removing a sliver of material about 1 4 inch wide depending on the model. For a cleaner cut put a strip of masking tape on the top and bottom of the sheet to keep chips from scratching the material. Given its dominance in the sheet metal cutting industry this article focuses on laser fusion cutting.

Manual sheet metal shears. The two most common types of laser cutting machines are fiber laser and co 2. If you need to cut small pieces of sheet metal an affordable baileigh manual shear saves space in your shop. For trimming small pieces rotary workbench shears can cut straight or.

Free shipping on many items browse your favorite brands. To prolong blade life rub wax along the length of the blade. Often called foot kick or stomp shears the manually operated table shears are the most economical way to accurately cut large pieces of sheet metal powered sheet metal shears can be air hydraulic or electro mechanical powered. Hydraulic powered shears are available for up to 1 4 inch thick steel.

Compound nibbler shears also provide some leverage for thicker metals. Co 2 lasers use an electromagnetically stimulated gas typically a mixture. Electric shears and double cutters are another common site in sheet metal shops which do small job shop types of cutting. These hand held tools are basically portable micro shears which chew away at the metal as you maneuver the cutting blade along its intended path.

Our hand metal shears are typically either pneumatic or electric powered for these tougher jobs. A hacksaw can cut sheet metal but its shape limits its turning radius and depth of cut. Our manual sheet metal shear line also includes rotary shear models that you can turn and manipulate to produce those nifty flowing curves. Vintage kepro 12 sheet metal shear guillotine cutting brake brass handle.

Fiber lasers vs co 2. Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force in this process the piece removed called the blank is not scrap but rather the desired part blanking can be used to cutout parts in almost any 2d shape but is most commonly used to cut workpieces with simple geometries that will be further shaped.